Industrial Inkjet Printers

Our Industrial Inkjet Printing Equipment:

See All

See All

See All

See All

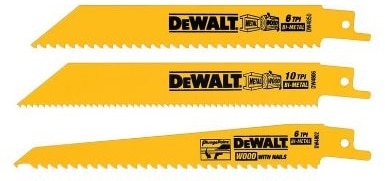

Saw blades marked on a singlepass inkjet printer

Engineered Printing Solutions offers a range of direct-to-object industrial inkjet printers (also sometimes referred to as “direct-to-shape” printers). We also design and build industrial inkjet printers that are completely customized, using the latest in inkjet technology and automation to meet your specific application.

The benefits of direct-to-object industrial inkjet printing are several. With no cups or plates to fill with ink, per-impression materials costs are much lower than with traditional contact forms of product-marking. With art stored digitally, there are no clichés to prepare and warehouse, which not only reduces costs but also means that changeovers can be near-instantaneous. (The fact that industrial inkjet printers use a four-color process—cyan, magenta, yellow, and black, with frequent use of white and varnish as well—further speeds changeovers, as there are often no spot colors to change.) Finally, by printing direct-to-object with industrial inkjet printing equipment, the additional tasks of inventorying, printing, and applying labels are eliminated, leading to further cost-savings.

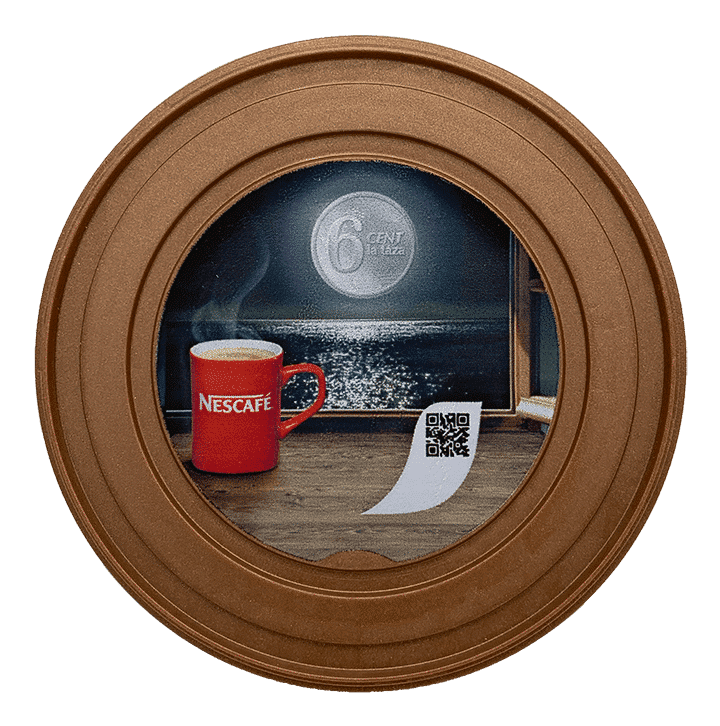

This product was marked on a cylindrical inkjet printer.

Today’s consumers demand mass-customization, and the quick changeovers and short-run capabilities of industrial inkjet printers make that possible. For some industrial print applications, the ability of high-speed inkjet production printers to print variable data on products or packaging means that high-speed batch-coding is possible. In a world where consumers demand cradle-to-grave traceability, industrial inkjet printers enable manufacturers to provide just that.

Single Pass Part-Decoration Examples

Industrial inkjet printers can decorate a wide variety of substrates and topologies. Here are just a few solutions we have designed and built in different industries: