Custom Solutions

Engineered Printing Solutions is constantly improving its capabilities and the equipment we offer our customers. We make R & D investments at our state-of-the-art facility to invent new ways of product decoration and marking. The benefits to our clients in greater flexibility and customization, faster throughput, and ultimately, greater profit are just one way in which we put our customers’ needs and vision first.

We discovered long ago that every customer’s needs are unique. What set us apart from our competition is that our sales and engineering teems will work closely with you from the initial assessment of the problem all the way to creative solution.

Custom Solutions

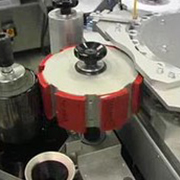

The XRV rotary pad printer is specifically designed for volume printing the measurements on the sides of syringes.

The XRV rotary pad printer is specifically designed for volume printing the measurements on the sides of syringes.Features

- One color with 360° vertical printing capability

- Diameter of the syringes from 10 to 40mm and length 70 to 100mm

- Bulk loading with conveyor system

- Constructed of stainless steel and aluminum for printing in a clean room environment

- Touch screen control, operator can change parameters and production requirements

- Ink circulating and mixing system

- Color density