Conveyors

Custom conveyors can be designed for many applications including post and/or pre-treating process during pad printing. Special fixtures can be designed to hold a particular substrate through the conveyor system.

Types of conveyors available are:

- Belt driven – Several types of materials and designs are available depending on the application.

- Linear

- Elliptical

- Gantry

Feeders

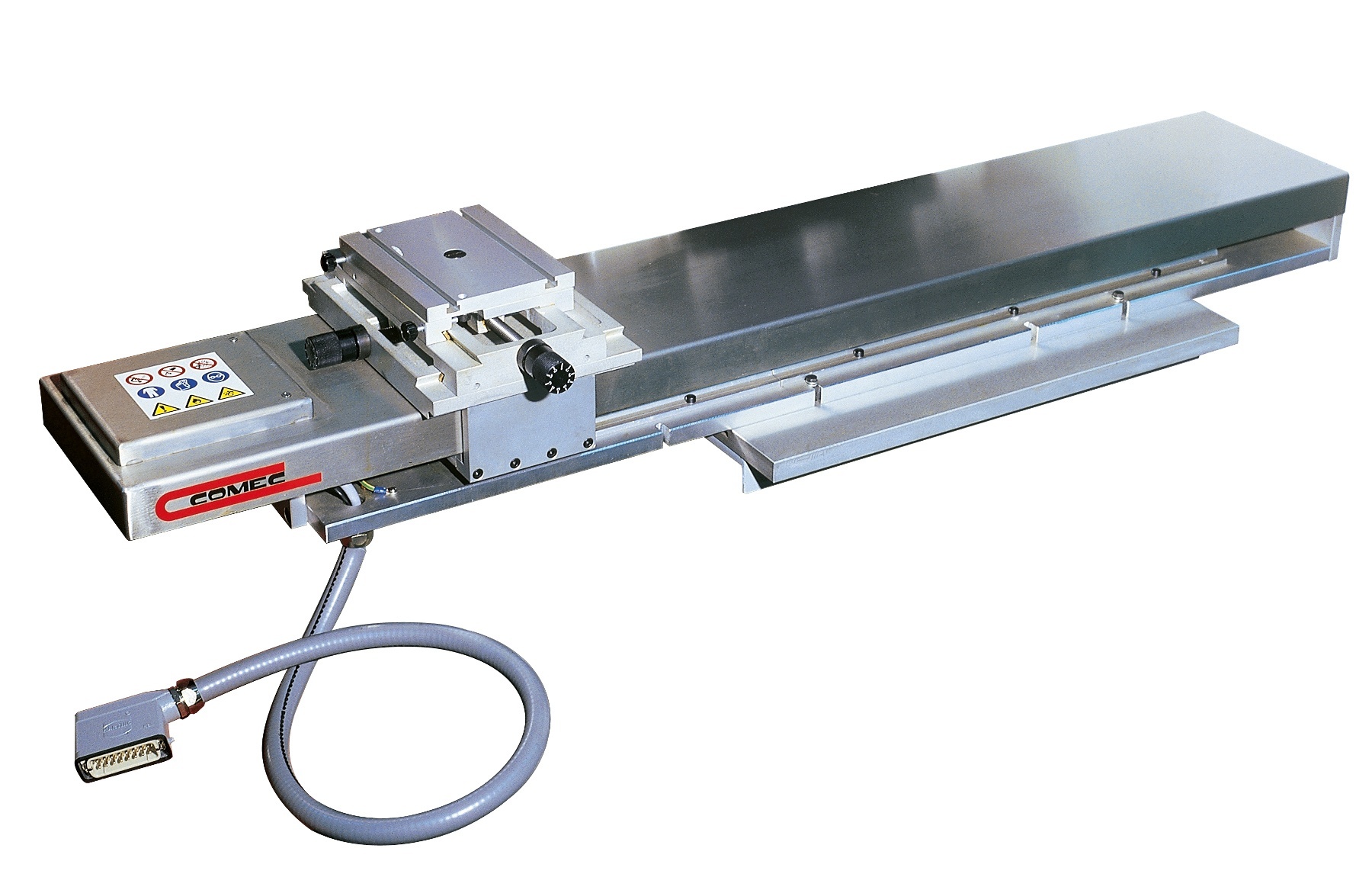

Linear conveyance is used primarily in multi-color and automated applications to increase hourly part output on machines with or without independent pads. This product is designed to allow multi-station printing on the same object in different locations and colors. The linear conveyor is electrically operated and controlled by a servo motor.

- Configurations include: from 18 up to 48 stations or more if required. Center to center on 127mm, 159mm, 191mm, 280mm or as required

- Advance distance is programmed directly from the machine’s touch screen

- Pick and place devices for automated product loading and/or unload stations and pre-treatment devices including flamers, corona or plasma can be integrated

Elliptical conveyance is used primarily in automated applications to increase hourly part output. This conveyor is for use on multi-color applications that require precise positioning to achieve perfect registration. This product is also suitable for printing single or double colors on two or four parts simultaneously. The elliptical conveyor is controlled by a servo motor or pneumatically with locking pins that control print registration.

- Configurations include: 12 stations for 4 colors, 14 stations for 5 colors, 16 stations for 6 colors

- Advance distance is programmed directly from the machine’s touch screen

- Pick and place devices for automated product loading and/or unload stations and pre-treatment devices including flamers, corona or plasma can be integrated

The linear shuttle comes standard with 500mm of travel length. This shuttle is programmable for a single part fixture, with an adjustable stop position between each pad station using the machines touch screen operator controls. Separate sequence changes are quick to program if necessary.

This type of shuttle is mainly used in four or five color pad machine applications with or without independent pad descents. This shuttle also works well along with robotic preload or unload applications.

- Electrically operated by a brushless servo motor

- Orthogonal table with XY registration and +/-5 degree rotation, allowing the placement of a part holder

- Configurable for automated product loading and/or unload stations

Available in pneumatic or as an electrically operated unit, rotary tables are primarily used to automate applications for one and two color registration. This device is also well-suited for secondary operations that require product preload, or unload and/or pre-and post-treatment stations.

- The rotary table can is programmable to advance 2, 4, 6, 8 or 12 individual stations.

- The aluminum surface has machined holes for fixtures with diameter up to 700mm on the standard model, or can be machined for larger custom applications as required.

Watch a rotary table in action:

Some applications include:

Some applications include:- Bottle caps

- Syringes

- Erasers

- Electric components

- Plastic parts

- Any parts that can be bowl fed