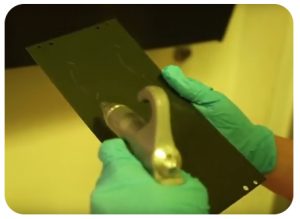

Cliché Development

Engineered Printing Solutions has the capability to develop a plate uniquely tailored to your pad printer. Our wealth of experience with inks and substrates ensures that we can create a plate that meets the demands of your personal application.

Engineered Printing Solutions has the capability to develop a plate uniquely tailored to your pad printer. Our wealth of experience with inks and substrates ensures that we can create a plate that meets the demands of your personal application.

Our plate department works closely with our Graphics Department to assure your artwork translates properly from the approved digital file to the cliché, and to your complete satisfaction.

Engineered Printing Solutions offers a complete line of printing plates, plate-making units and pad printing consumables.

- We’ll factor in the length of the job and the technical requirements.

- We look at how the product will be handled by the end-user

- Determine what course of action needs to be followed.

- And, if and when your job changes, we’ll do it all over again to make sure you look good

Polymer Plates

Alcohol or Water Wash – When selecting polymer plate material, cost and number of impressions are a determining factors. Polymer plates come in different hardness and are rated for jobs that run as few as 10,000 impressions to projects that extend for 70,000 impressions, or more.

- Consist of a steel backing layer

- Layer of UV sensitive nylon

- Removable protective coating

Thin Steel Plates

.018″ or .020″ thick – For runs up to 500,000 impressions with a closed cup system, and less than 100,000 with an open well system and are available in various sizes up to 7.874″ wide, both in etched and unetched plates.

- Bright polish carbon steel

- Rockwell hardness of 48-52

- Flatness of 0.2%

Information needed when ordering a plate

- What plate material are you ordering?

- What size (width by length) do you need?

- How many plates do you want to order?

- Do you want us to punch holes in the plates for you?

- Do you want us to etch the plates for you?

- Do/If you etch your own plates, do you need any more supplies?

Art Requirements

Click here to view Art Requirements for plate making.