Case Study: Hodges Badge Company Converts to Cold-Foil Printing

For over 100 years, Hodges Badge Company has been a family-owned and operated business selling awards, ribbons, and rosettes for every occasion, from dog shows to academic and sporting events to corporate awards. Recently, the company approached Engineered Printing Solutions about making the leap from hot-foil stamping production to cold-foil printing. We designed and built a machine for the company, and they haven’t looked back since.

For over 100 years, Hodges Badge Company has been a family-owned and operated business selling awards, ribbons, and rosettes for every occasion, from dog shows to academic and sporting events to corporate awards. Recently, the company approached Engineered Printing Solutions about making the leap from hot-foil stamping production to cold-foil printing. We designed and built a machine for the company, and they haven’t looked back since.

Rick Hodges, President, Hodges Badge Company

We have written in the past about the advantages of cold-foil printing over hot-foil stamping, but Rick Hodges, president of the company, summarized the benefits in a recent phone call. “With no dies to make, our lead times went from two days to two hours”. In addition, the quality of their designs went up, as the company was able to produce finer lines than they could with hot-stamping, which sometimes produces “bridging” between two lines when excess foil is applied. This is not a problem with cold-foil printing, said Hodges. Hodges also cited the cost-savings of not having to warehouse dies for future use as an additional benefit of going the cold-foil printing route.

Converting from traditional production methods to cutting-edge cold-foil printing is not without its challenges however, warned Hodges. “There is a bit of a learning curve, as digital inkjet printing requires a completely different skillset than traditional tool-and-die manufacturing,” he noted. Hodges credited EPS’ after-sales service and support for getting the badge company up to speed.

And speed is what attracted Hodges to the idea of cold-foil printing in the first place. The speed-to-market advantage of cold-foil printed products over conventionally-produced products means that there are whole new markets that Hodges Badge Company can serve that simply aren’t economically feasible using conventional methods with their tooling costs. Variable-data products and runs-of-one become viable options using cold-foil printing.

Hodges intends to hold on to its first-mover advantage when it comes to cold-foil printing. “None of my competition can match the quality, variety, and speed-to-market of our products,” he said, and he doesn’t foresee that changing any time soon.

Do you need award ribbons, medals, trophies, or other memorabilia? Contact Hodges Badge Company today. And to learn more about cold-foil printing, drop us a line!

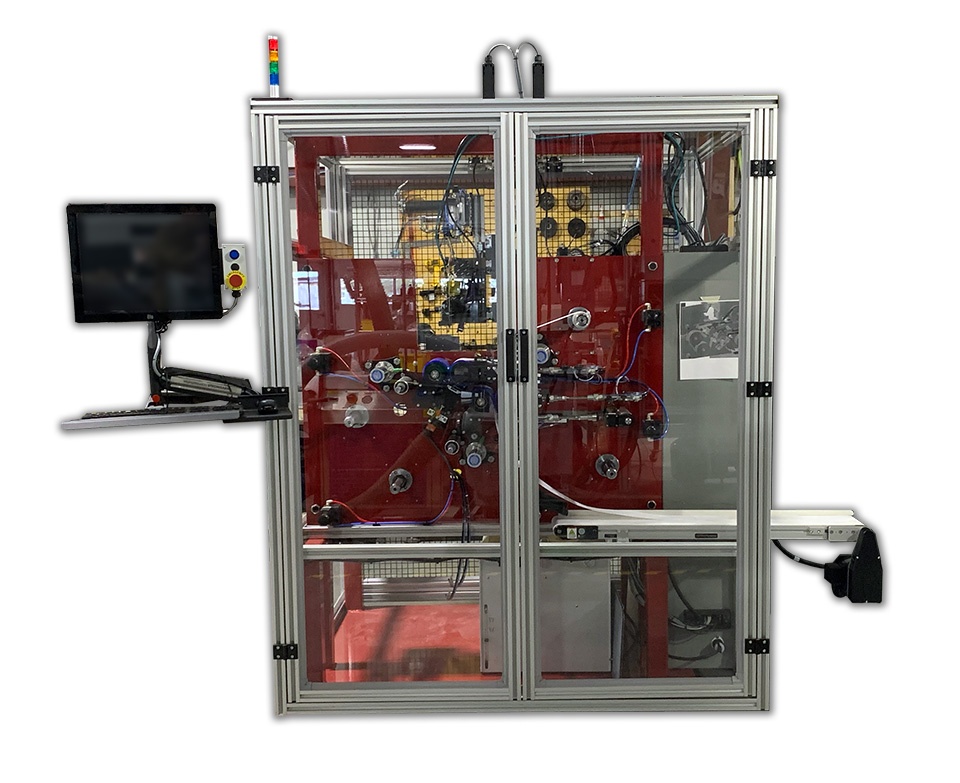

This industrial inkjet printer jets UV-curable adhesive that instantly bonds the cold foil to the substrate.